Process monitoring with Machine Vision

Your processes always in view: Why Machine Vision is crucial

Effective process monitoring is crucial to the success of a company. By constantly improving and optimizing processes, costs can be reduced, quality improved and productivity increased. However, traditional methods of process monitoring, such as manual inspections or the integration of simple sensor technology, often reach their limits, especially when complex or fine processes are involved.

Manual inspections often take a lot of time and are prone to human error. Although simple sensors can monitor certain parameters, they are often unable to detect subtle changes or patterns that could indicate problems in the process. As a result, potential problems are not recognized until they have already led to significant costs or quality problems.

Image processing systems such as the evoVIU smart camera offer an innovative solution for process monitoring. The finest details that are invisible to the naked eye can be captured and analyzed. This enables precise monitoring and control of processes.

What processes are we actually talking about?

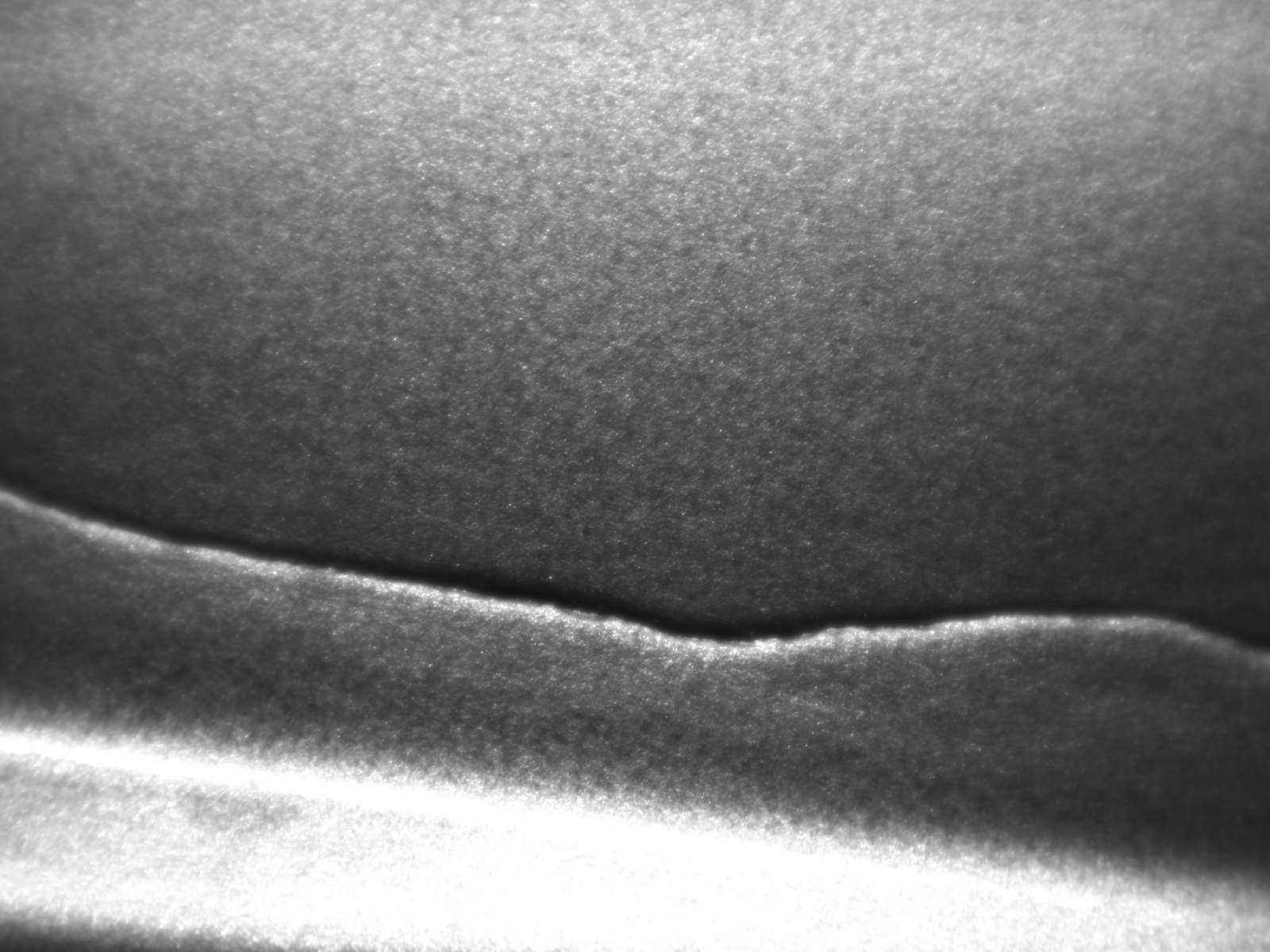

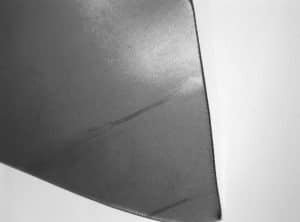

There are a variety of processes that can benefit from monitoring using Machine Vision. One of the obvious applications is product quality control. Image processing systems can detect the finest defects or irregularities on surfaces that would be difficult or impossible for the naked eye to see. This is particularly important in industries such as the automotive industry, electronics manufacturing or food production, where even the smallest defects can affect the safety or functionality of the end product.

Machine vision systems are also ideal for monitoring production processes. For example, they can check the correct positioning of parts or components, monitor the alignment of workpieces or check the correct functioning of machines. This is crucial to ensure high production quality and reduce waste.

Another area of application is the detection of errors in assembly processes. Machine vision systems can automatically check whether components have been assembled correctly or whether assembly steps have been carried out in the correct sequence. This allows errors to be detected and rectified at an early stage before they lead to major problems.

In addition to simple fault detection, image processing systems can also be used to monitor packaging and labeling processes. You can ensure that packaging is properly sealed, labels are correctly applied and the right products are placed in the right packaging. This is particularly important in industries such as pharmaceuticals or the food industry, where strict regulations and high quality standards apply.

Overall, the precise recording and analysis of visual data by image processing systems enables reliable monitoring of a wide range of processes. Companies can identify potential problems at an early stage and intervene proactively to minimize downtime and increase efficiency. Through the targeted use of image processing technology, they can optimize their production processes and strengthen their competitiveness.

Process monitoring in practice

The following practical example can illustrate the effectiveness of image processing systems for process monitoring: In a production plant, smart cameras are used to check the surfaces of components for the smallest defects. As soon as a defect has been detected by the automatic detection, the faulty parts can be sorted out. This can drastically reduce reject rates and significantly improve product quality.

A typical method for sorting out faulty parts in a production process is the use of signals sent to a control system. As soon as a defect is detected, the image processing system can send a signal to the machine to sort out the faulty part. This can be done, for example, by activating a pneumatic system that removes the faulty part from the production line. Alternatively, the data can also be sent to a higher-level control system, which then forwards the corresponding instructions to the machines.

Another practical example of process monitoring is quality assurance in the food industry. By using image processing systems, production lines can be continuously monitored to ensure that products meet the required quality standards. The cameras capture images of the products as they move along the line and analyze them in real time. Algorithms are used to detect deviations from the specified parameters, such as color deviations, shape errors or foreign objects. This allows errors to be detected at an early stage and measures to optimize processes to be taken. Process monitoring through Machine Vision enables efficient and precise quality control, which can lead to higher productivity and customer satisfaction.

When does an image processing system make sense for process monitoring?

Nevertheless, the decision to use Machine Vision for process monitoring should be made carefully. There are many different systems on the market, from which you have to choose which one makes the most sense for the respective use case. But the search for the perfect system is worthwhile if you have complex or fine processes where conventional methods reach their limits. Machine Vision can be an effective solution here.

However, it is important to note that Machine Vision is not always the best solution for every surveillance problem. In some cases, simple sensors or manual inspections may be sufficient, especially if the processes are not very complex or if the cost of implementing vision systems is too high. Companies should therefore carefully consider their specific requirements and constraints before deciding to implement Machine Vision.

In addition to these considerations, there are other aspects that should be taken into account:

-

Flexibility and adaptability: A vision system can prove to be extremely flexible, as it can often be easily adapted to different processes and requirements. It can take into account parameters such as lighting conditions, surface finishes and product variants, making it ideal for applications that require a high degree of adaptability.

-

Real-time monitoring and feedback: Machine vision systems can often operate in real time, providing immediate feedback on the status of the process. This can help to identify potential problems at an early stage and make immediate corrections, improving the efficiency and quality of the process.

-

Data analysis and potential for improvement: By integrating vision systems into process monitoring, companies can also collect extensive data about their production processes. This data can be analyzed to detect trends, identify bottlenecks and uncover opportunities for optimization, leading to continuous process improvement in the long term.

-

Compliance and quality standards: In industries where strict quality standards and compliance requirements apply, implementing a vision system can help to meet these standards and ensure the quality of end products. This is particularly important in areas such as the food and pharmaceutical industries, where accuracy and consistency are crucial.

-

Future viability and innovation: Machine Vision technology is constantly evolving and new advances make it possible to implement ever more sophisticated applications. By investing in machine vision systems, companies are not only positioning themselves for current requirements, but also for future innovations and competitive advantages.

What are the advantages and disadvantages?

Machine vision systems offer both advantages and disadvantages in process monitoring. One of its main advantages is its ability to analyze large amounts of visual data in real time. This allows errors or irregularities in the production process to be detected and rectified quickly, which improves productivity and efficiency. Machine Vision also enables precise measurement and control of quality standards, resulting in better overall product quality. The automation of processes is another advantage, as image processing systems can take over repetitive tasks, which reduces the workload of employees.

Another advantage is the ability to collect and analyze data. Machine vision systems can collect extensive data on production processes, which can then be analyzed to identify trends and uncover potential for optimization.

However, there are also some disadvantages to consider. Machine vision systems require careful calibration and regular maintenance to deliver reliable results. This may require additional time and resources. In addition, the acquisition and implementation costs are often high, especially for customized solutions. Training employees to use the systems can also be costly. Due to their complexity, familiarization with image processing technologies can have a steep learning curve, which can lead to initial difficulties.

It is important to emphasize that Machine Vision is not the best solution for every application. In some cases, simple sensors or manual inspections can offer more cost-effective and efficient options. Companies should therefore carefully consider their specific requirements and limitations before deciding to implement vision systems. Despite the challenges, machine vision systems offer great potential for process monitoring and can help companies to optimize their production processes.

The decision has been made: But what's the best way to start?

In order to start implementing Machine Vision for process monitoring, it is advisable to first carry out a thorough analysis of the existing processes. Potential weaknesses should be identified and targets for improvement set. Various vision systems can then be evaluated in order to select the most suitable one for the company’s specific requirements. You are welcome to get in touch with us and perhaps also benefit from the fact that you can borrow a camera for the time being. You can test over several weeks or months whether and how the system works best for you. Because one thing is certain: with careful planning and implementation, companies can fully exploit the benefits of Machine Vision and effectively optimize their processes.

Overall, it can be said that process monitoring using Machine Vision is an effective method for the continuous improvement and optimization of processes. The use of modern technologies and algorithms not only reduces costs, but also improves quality and increases productivity. This offers companies the opportunity to remain competitive and further increase their efficiency. With a view to the future, it is therefore advisable to fully exploit the potential of process monitoring through Machine Vision and to closely follow current developments in this area.

Other contributions:

Finally: The new VIU2 PoE camera is here!

The VIU2 PoE camera is here! You can find out why PoE is an important feature in this article.

Finally: The new VIU2 PoE camera is here!

The VIU2 PoE camera is here! You can find out why PoE is an important feature in this article.

5 real-life smart city examples

What smart city examples are there? You can find out in this blog article.

Object recognition with Machine Vision

Object detection is an important way for many industries to sort out faulty components.

Process monitoring through Machine Vision: 100% effective and efficient!

Process monitoring with Machine Vision Your processes always in view: Why Machine Vision is crucial Effective process monitoring is crucial to the success of a

New Teamcity Build Agent

We got a new Teamcity build agent last week. Read here how exactly we benefit from this!

Crack detection in the pressing plant

Cracks on components manufactured in the press shop can often be detected at an early stage. Find out more about this use case.

Different light colors

How important is the color of light in the choice of light for an image processing system? What are the differences?

How does face recognition work?

Most of us are confronted with it every day: Facial recognition. But how does it actually work?

Smart Camera in a CNC machine?

An evoVIU has been hanging in our CNC machine for a few months now. Here’s our why, how, and a look at how it’s worked so far.

Classic Machine Vision vs Machine Vision with AI

What actually distinguishes classical Machine Vision from Machine Vision that uses AI? Is AI always better?

Saving images in image processing projects

What actually happens to the vast quantities of images that you take every day if you have an integrated image processing system?

What is the procedure for an image processing project?

What actually happens after you realize that you can solve an existing problem with an image processing system?

Release of the evoPowerbank

We have released the evoPowerbank – a battery adapter for industry that supplies power where no fixed supply is possible.

Machine Visionas a solution to the shortage of skilled workers?

Germany as a business location is currently being put to the test. Can Machine Visionimprove the skills crisis?

Potential Industry Sectors for Smart Cameras

Smart cameras are used in many different industries. There are new challenges in every industry.

OCR – What does it mean?

OCR is a text recognition technology. Using OCR, it is possible to convert analog text into machine-readable characters.

Energy consumption of the Smart Camera evoVIU as an embedded camera system

Shop Energy consumption of the evoVIU as an embedded camera How much power does the evoVIU consume? The headlines on the subject of rising energy